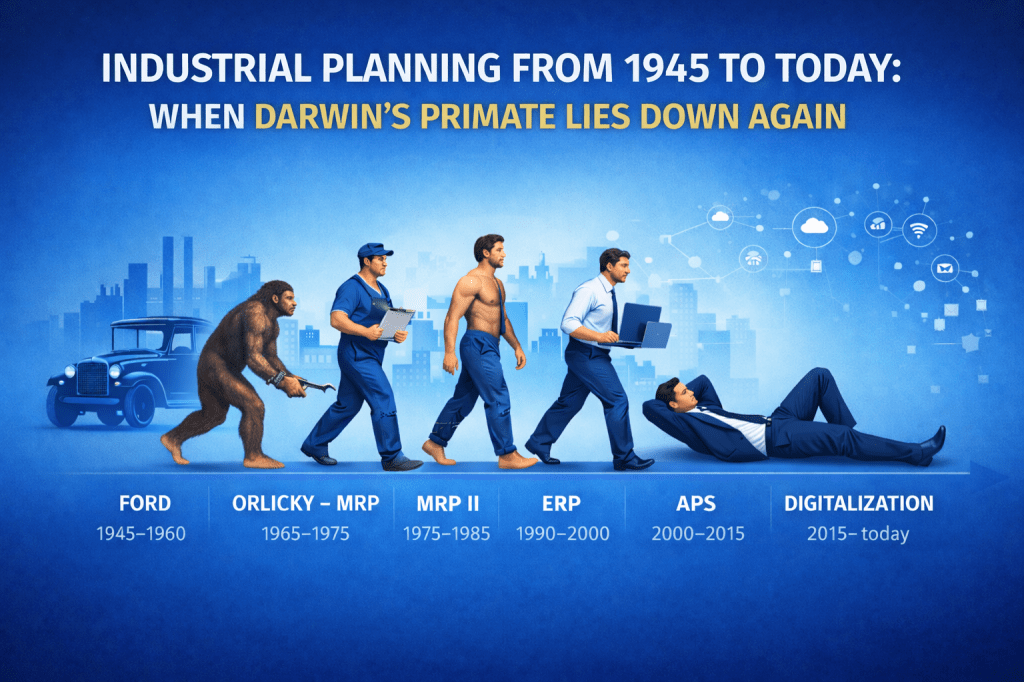

Industrial Planning from 1945 to Today: Continuity, Discipline, and the Illusion of Disruption

Since the end of World War II, industrial planning has evolved through a series of deliberate, cumulative advancements rather than disruptive revolutions. While digital technologies, Advanced Planning & Scheduling (APS), and artificial intelligence have dramatically accelerated decision-making, they have not altered the foundational logic of planning. Organizations that deliver sustainable performance are those that recognize this continuity, preserve the discipline of progressive planning, and leverage technology to amplify — not replace — proven principles.

This article outlines the historical evolution of industrial planning, highlights the enduring relevance of the MRP II–derived planning hierarchy, and draws implications for modern leaders navigating digital transformation.

1. A Historical Perspective: Progress Through Accumulation

1.1 Post-War Foundations (1945–1960): Simplicity as Strategy

In the immediate post-war period, industrial planning was shaped by reconstruction imperatives. Inspired by Fordist principles, production systems were characterized by linear flows, simple product structures, and pragmatic push-based planning. This simplicity was not a limitation but a strategic choice, enabling reliability and repeatability in a constrained environment.

The essential contribution of this era was the formalization of production organization — establishing the first building blocks of structured industrial planning.

1.2 Visibility and Anticipation (1965–1975): The Emergence of MRP

The introduction of Material Requirements Planning (MRP), driven by Joseph Orlicky, marked a decisive step forward. For the first time, material needs could be calculated, visualized, and anticipated through structured bills of materials and time-phased planning.

Planning shifted from reactive execution to anticipatory coordination. Inventory management became disciplined, and decision-making gained consistency and predictability.

1.3 Integrated Planning (1975–1985): MRP II and the Closure of the Loop

Manufacturing Resource Planning (MRP II) extended the MRP logic by integrating capacity management, scheduling, and Sales & Operations Planning (S&OP). This closed-loop architecture aligned demand, supply, and resources within a coherent planning framework.

MRP II established a hierarchical decision structure that allowed organizations to manage increasing product and process complexity without sacrificing control.

1.4 Enterprise Discipline (1990s): ERP as a Scaling Mechanism

Enterprise Resource Planning (ERP) systems did not redefine planning concepts; instead, they industrialized them. By standardizing processes and integrating planning across functions and geographies, ERP solutions embedded operational discipline at scale.

The underlying planning logic remained unchanged — but its consistency and reach expanded dramatically.

1.5 Sophistication and Optionality (2000s): APS and Finite Capacity

Advanced Planning & Scheduling solutions introduced finite-capacity constraints, optimization techniques, and scenario simulation. These capabilities enhanced decision quality and responsiveness, particularly in complex manufacturing environments.

Critically, APS tools remained dependent on the hierarchical planning foundations established by MRP II. They refined decisions; they did not replace the planning sequence.

1.6 Acceleration Without Rupture (2015–Today): Digitalization and Analytics

The current wave of digitalization — real-time data, advanced analytics, artificial intelligence, and connected ecosystems — has transformed the speed, visibility, and granularity of planning and execution.

Yet, despite their power, these technologies remain structurally anchored in historical planning principles. Digital execution without structured planning simply accelerates instability.

2. The Enduring Value of Progressive Planning

2.1 The Planning Hierarchy as a Structural Asset

The progressive planning model inherited from MRP II — articulated through the S&OP → Master Production Schedule (MPS) → Detailed Scheduling sequence — remains a cornerstone of effective industrial planning.

Each level of this hierarchy serves a distinct purpose:

- S&OP aligns demand, supply, and strategic objectives over a mid- to long-term horizon.

- MPS translates aggregate plans into feasible production commitments.

- Detailed Scheduling operationalizes decisions at execution level, within finite constraints.

This structure ensures coherence across time horizons, decision granularity, and organizational responsibilities.

2.2 Technology as an Amplifier, Not a Substitute

Modern planning tools compress cycles, enhance analytical depth, and enable rapid scenario evaluation. However, they do not eliminate the need for hierarchical sequencing and disciplined decision-making.

When organizations attempt to bypass this structure in the name of agility or innovation, they typically reintroduce variability, increase operational risk, and amplify errors at scale.

3. Implications for Industrial Leaders

Industrial transformation initiatives should be guided by three fundamental principles:

- Continuity over disruption: Innovation must be understood as an extension of proven planning logic, not a rejection of it.

- Structural discipline: Planning hierarchies are not legacy constraints but performance enablers.

- Experience before algorithms: Technology delivers value only when it reinforces human expertise and organizational learning.

Organizations that internalize these principles achieve faster execution, higher reliability, and more resilient operations.

Conclusion: Memory Before Novelty

For more than seven decades, industrial planning has progressed through accumulated knowledge rather than abrupt revolutions. The most successful organizations are those that understand why historical models worked, how they evolved, and how modern technologies can enhance — rather than override — this legacy.

In industrial planning, sustainable performance belongs to those who respect the past, master the present, and evolve with intent.

Emmanuel de Ryckel

Leave a comment